01 Introduction

As the global solar industry surges forward, a less-visible challenge is rising in parallel: what to do with the growing volume of aging or end-of-life (EoL) photovoltaic (PV) modules. The first major waves of solar installations—deployed 15 to 20 years ago—are now reaching the point where performance degradation, technical failures, or repowering needs make recycling increasingly important. Rather than treating these panels as waste, today’s circular-economy approach views them as valuable sources of materials that can be recovered, reused, and reintegrated into new products.

This shift is not only environmentally responsible—it is also becoming economically viable. Understanding what PV modules contain, and how those materials are extracted, is the foundation of modern solar-panel recycling. Here is a clear breakdown of the materials inside a typical crystalline-silicon PV module and how recycling them works.

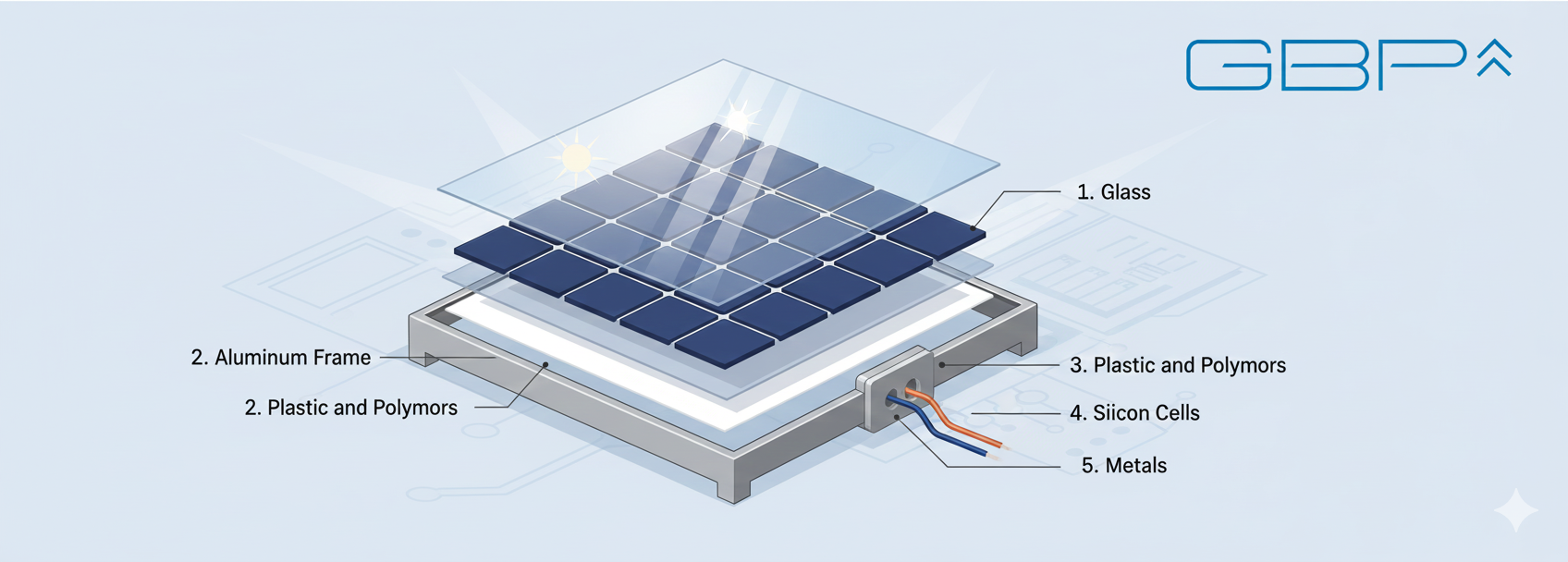

02 What’s Inside a PV Module? The Material Composition

Crystalline-silicon (c-Si) modules—used in more than 90% of solar installations—are built in layers, each serving a structural or electrical function. A standard 20–25 kg panel contains the following materials:

1. Glass (≈ 65–75% of total weight)

Glass is the single largest component of a PV module and forms the protective front surface. High-strength tempered glass is used to withstand outdoor conditions for decades. Because glass is easily recyclable with mature industrial processes, it represents one of the most recoverable materials during recycling.

2. Aluminum Frame (≈ 10–15%)

The aluminum frame provides rigidity and support. Aluminum is one of the most valuable and recyclable components in a solar panel. Removing it is also one of the simplest steps in the recycling process.

3. Plastics & Polymers (≈ 10%) — EVA & Backsheet

EVA (ethylene-vinyl acetate) acts as an encapsulant that bonds the layers together, while the backsheet provides environmental protection. These polymer layers are the most challenging materials to separate because they are heat-bonded and must be treated during mechanical or thermal processing.

4. Silicon Cells (≈ 3–5%)

The silicon wafers form the electricity-generating core of the module. Although the weight percentage is small, silicon recovery is essential for energy and resource efficiency. High-purity silicon can be reused in electronics or reprocessed into new solar-grade materials.

5. Metals — Silver, Copper, Tin (≈ 1–2%)

Silver is the most valuable material in a PV module, used in the grid lines printed onto each cell. Copper wiring and soldered joints contain trace amounts of tin and sometimes lead. Recovering these metals is critical for economic and environmental reasons, but requires specialized processing.

03 Step-by-Step: How PV Module Recycling Works

Recycling is often divided into three main methods—mechanical, thermal, and chemical. In practice, large-scale recyclers may combine techniques to maximize material recovery.

Step 1: Manual Disassembly

The process begins with removing the aluminum frame, junction box, and external cables. This step is quick, safe, and allows the immediate recovery of high-purity aluminum and copper.

Outcome:

・Clean aluminum fractions

・Copper wiring

・Plastic junction-box components

Step 2: Mechanical Processing

The remaining laminate—glass, silicon, EVA, and backsheet—is put through mechanical treatment. Panels are crushed or shredded into smaller pieces, allowing separation of glass from other materials.

Recovered through mechanical steps:

・Glass cullet: Often 70–90% purity, used for insulation or glass products

・Metal fragments: Silver and copper traces

・Silicon fragments: To be further purified

Mechanical recycling is widely used due to its scalability and lower operating costs.

Step 3: Thermal Processing (Delamination)

Thermal treatment heats the shredded materials to melt and evaporate polymers like EVA. This frees the silicon cells and metal contacts.

Benefits:

・Efficient separation of silicon wafers

・Removal of plastic layers

・Improved purity of recovered materials

However, this method requires energy input and must be operated with emissions controls.

Step 4: Chemical Processing (Refining High-Value Materials)

Chemical leaching or etching is used to extract precious metals such as silver, copper, and tin from the remaining material streams.

Results:

・Recovered silver paste

・Copper conductors

・High-purity silicon for reuse

This step maximizes economic recovery, though it is typically used only for selected high-value material flows.

04 Why Recycling Matters: Economic & Environmental Impact

1. Conserving Valuable Resources

Silver and silicon are finite materials with growing demand. Efficient recycling reduces pressure on mining and production, supporting long-term supply security.

2. Supporting Circular-Economy Goals

By recovering up to 85–95% of a panel’s materials, recycling significantly reduces waste volumes and supports ESG objectives for owners and operators.

3. Preparing for a Future Wave of Solar Waste

International agencies predict that global PV waste will reach several million tons by 2050. Establishing recycling infrastructure today ensures responsible management on a national and global scale.

4. Enabling Sustainable Repowering

As more solar farms replace older modules with higher-efficiency ones, recycling allows decommissioned panels to re-enter the material supply chain instead of landfills.

05 The Role of Companies Like GBP in the Circular Solar Economy

With its expertise in solar panel replacement and lifecycle management, GBP is positioned to help shape a more sustainable future for the industry. By integrating recycling into repowering solutions, GBP ensures that clients not only upgrade performance but also handle decommissioned materials responsibly.

Whether through consulting, material recovery partnerships, or end-to-end project support, GBP can offer clients a compliant, environmentally sound approach that aligns with global best practices.