GBP Expands Maintenance Box Lineup with New Resin Cover Option, Enhancing Worksite Efficiency and Safety

- 2025/10/22

- News

Tokyo, Japan – GBP K.K., a rapidly growing leader in the renewable energy industry known for its advanced technologies in renewable energy, EV components, and AI/IoT integration, has announced a new resin material option for the lid of its Maintenance Box.

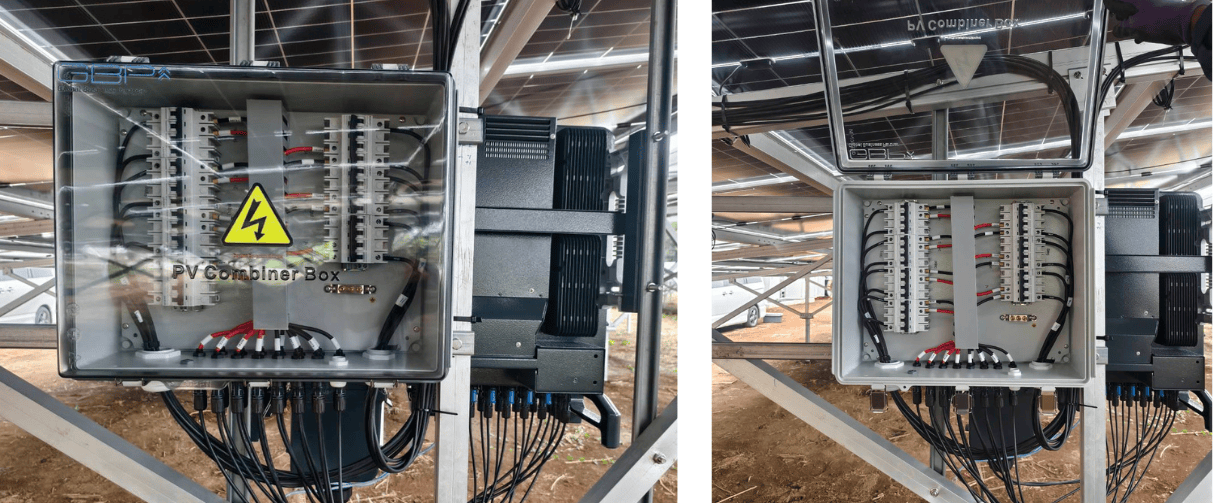

This upgrade adds to the existing lineup of steel and stainless-steel covers, offering a lighter, safer, and more efficient solution for inspection and maintenance at solar power plants. The new resin cover allows visual inspection of internal components from the outside, dramatically improving both safety and operational efficiency on site.

Faster, Safer, Smarter: Why Resin Material Covers Are the Future

The newly added resin cover option is designed with on-site performance and safety in mind, helping technicians save valuable time during regular inspections and maintenance.

✅ See Inside Without Opening

The transparent resin lid allows users to visually check the status of breakers and components without opening the box, reducing manual work and inspection time.

✅ Safe Maintenance in Bad Weather

When maintenance work is difficult during rain or strong wind, the transparent lid enables external visibility, making inspections safer and more efficient.

✅ Suitable for Installation Under Solar Panels

The Maintenance Box can be easily installed under solar panels in shaded areas, ensuring flexibility in system design and layout.

Customer Feedback: Proven Performance in the Field

“We were initially considering purchasing a junction box, but after discovering GBP’s Maintenance Box, we decided to order 125 units. Impressed by its performance and reliability, we later placed an additional order for 300 more units.”

Many clients in the solar power sector have praised GBP’s Maintenance Box for significantly reducing maintenance time and operational burden — contributing to greater efficiency in solar power plant operations.

Key Features of GBP’s Maintenance Box

GBP’s Maintenance Box is the first of its kind in the industry, integrating opening, disconnection, and inspection functions into a single enclosure. This innovative structure streamlines operations, reduces project timelines, and cuts overall maintenance costs.

No need to disconnect strings during maintenance — Supports MPPT function and accommodates 2–4 circuit strings per unit.

Work without stopping the PCS (Power Conditioner) — Enables inspection per string without circuit disconnection.

Reduced risk of terminal failure and fire — High-quality design minimizes long-term wear and enhances safety.

Eliminates wiring errors — Saves up to 80% of maintenance time, significantly lowering long-term O&M costs.

Customizable design — Input/output voltage and circuit numbers can be tailored to project requirements.

Japanese engineering support — Dedicated technical teams ensure reliable assistance throughout the product lifecycle.

Comprehensive insurance coverage — GBP products are backed by major Japanese insurance partners for fire or accident protection.